Project Description

Arconic K2 hall, Székesfehérvár, 2018

The Arconic K2 building is an industrial facility of approximately 20,000 sq.m. with prefabricated reinforced concrete structure. The product development was carried out by Plan31 Mérnök Kft.

Basically two buildings were built that can be easily separated: an F+1 level office building which is suitable to accommodate one additional level later on and a large industrial hall with quite complicated layout and height conditions i.e. with a lot of negative and positive corners, level changes, in some places intermediate reinforced concrete floors flowing in in clouds. In the majority of the floor area travelling cranes are installed and there are varied alignment reinforced concrete firewalls, and thermally insulated reinforced concrete sandwich base panels.

Short principal beam reinforced concrete structural skeleton was used in this hall i.e. the principal beams (IP120/60) were installed on the shorter, 15 m line of the 15×30 m base grid and the purlins (ITS145/60, ITS154/60 – height increase because of snow load) in the 30 m direction, with 7.50 m divisions.

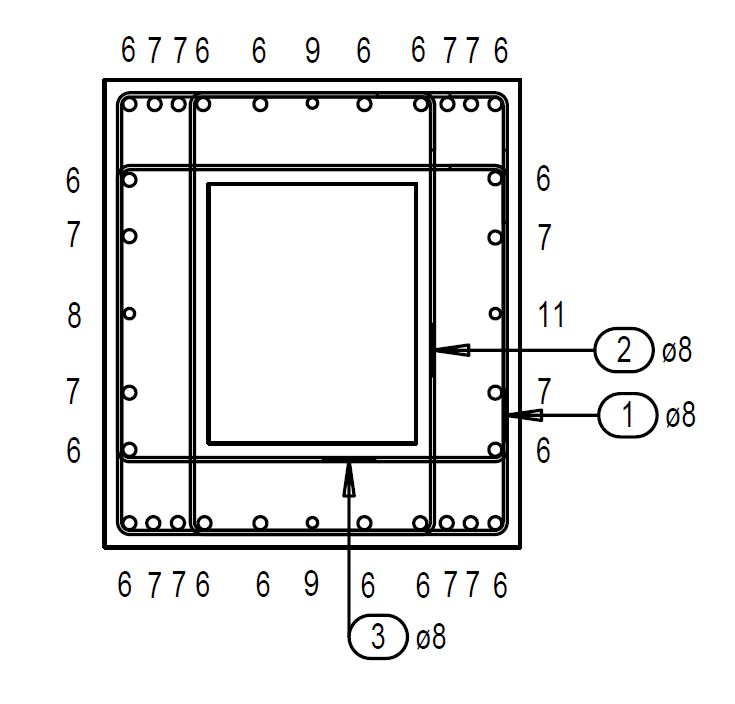

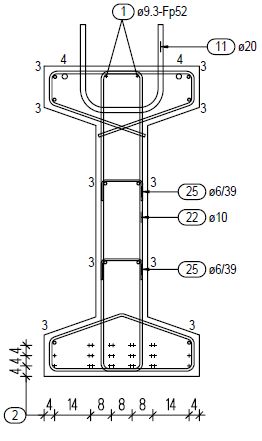

A unique solution was applied during the structure of pillars which have a 80/90 cm cross-section and 18.50 m length. As the solid reinforced concrete elements would have far exceeded the weight limit of 30 tons for production line options, we had to reduce the weight with polystyrene inserts, while paying attention to not to experience any perceptible deterioration in the pillar indicators of stiffness, and to not to experience any statical problems when introducing local loads (beam bending tension, crane base, lifting tube).

During the design phase we prepared the 3D model of the complete reinforced concrete shell at first so that we could provide the design/execution partners with it before preparing the product designs. Simultaneously with preparing the model we prepared the statics calculations. On the one hand this consisted of determining the dimensions of the prestressed reinforced beams because there are beams of large span in the building. It is important for us to work with economical segments and dimensions. On the other hand we performed secondary calculations of several typical frames when determining the dimensions of the pillars; these approach reality better than the generally used primary calculations.

Processing started after that; allocation (designation) designs were prepared of the reinforced concrete components – bowls, pillars, intermediate floor, roof beams, pedestal and wall components, docking stations, firewalls, stairs, armatures etc. – and then shuttering and reinforcement plans were prepared.

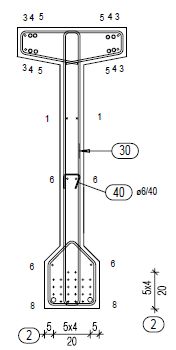

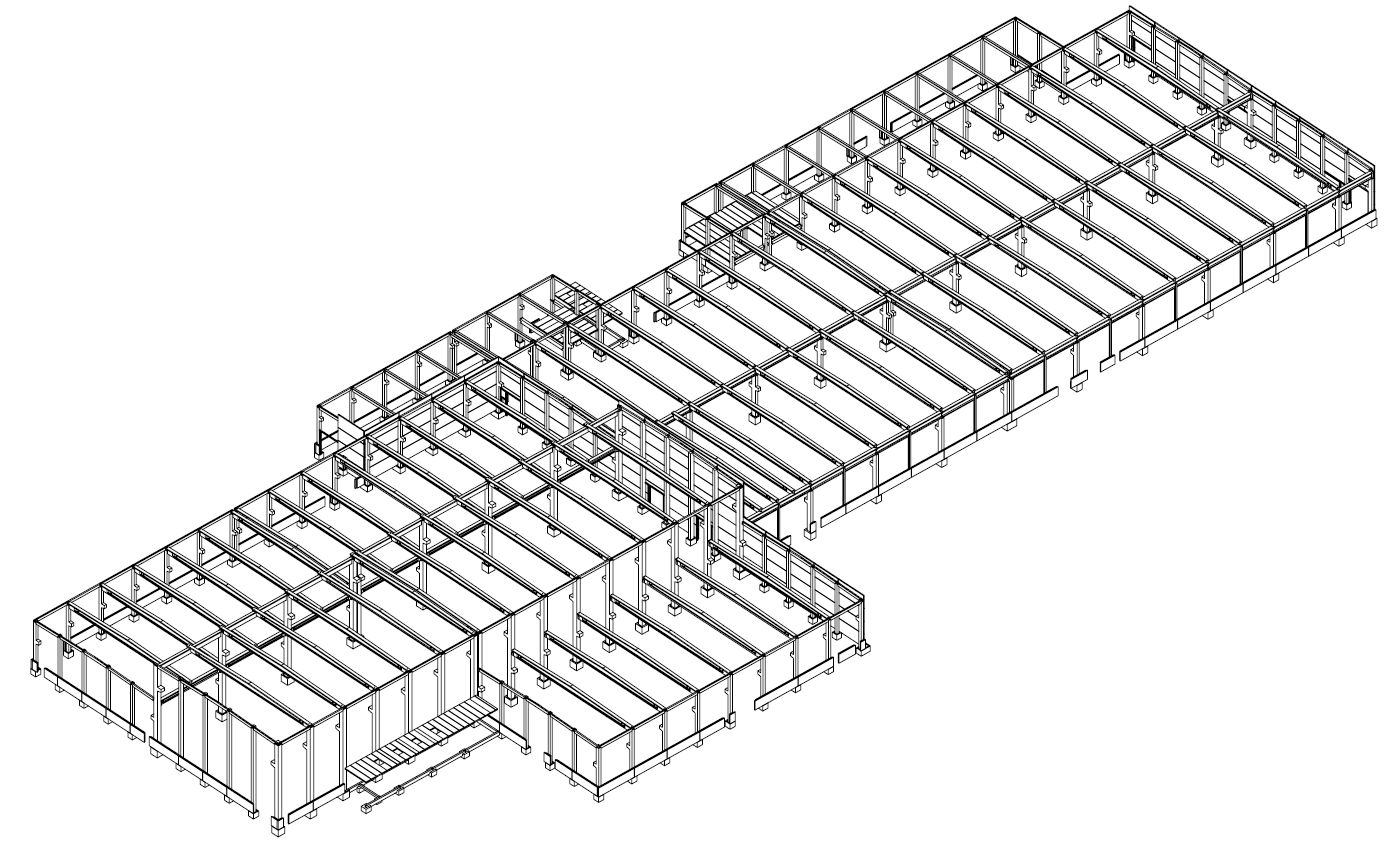

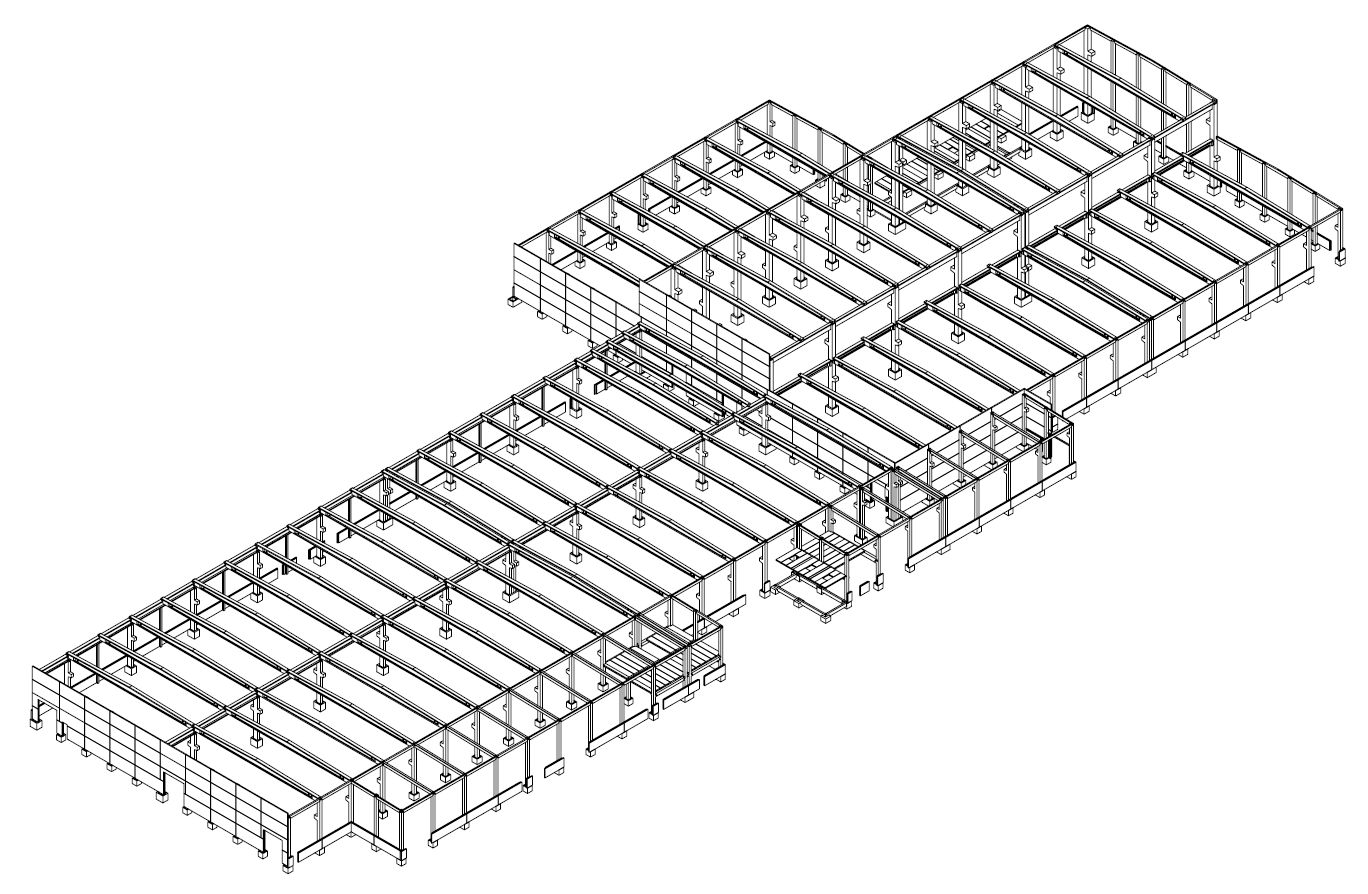

Axonometry

Common building elements used in the project

Cross-section of pillars

Cross-section of principal beam

Cross-section of principal beam