Project Description

Ikea furniture store, Soroksár, 2016

The Ikea furniture store at Soroksár is an industrial facility of approximately ~22,000 sq.m. with prefabricated reinforced concrete structure. The product development was carried out by Plan31 Mérnök Kft.

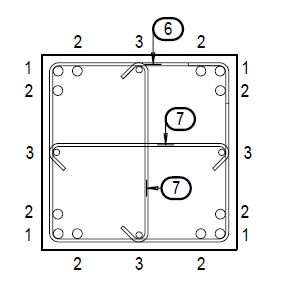

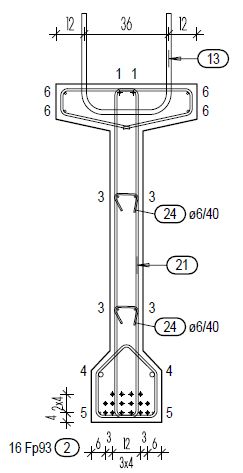

The structure of the building above the relief is prefabricated reinforced concrete structure. These are sporadically supplemented by monolith reinforced concrete elevator shafts, staircases and fire zone bordering walls. The system of the load-bearing structures is the following: the 50 x 50 cm reinforced concrete pillars were installed into the bowl foundations fixed in pile heads. The pillars have one or two levels depending on their location i.e. whether they are in the sparse grid points of the floors or not. In the areas with intermediate floors pillars fitted to every third grid line are 2-level ones, while the pillars in between on two grid lines are 1-level pillars. An 8 x 16 m pillar grid was designed in the ground floor while on the upper floor and the single story high-bay warehouse with large clear height a 24 x 16 m grid was designed. The wall structure pillars are connected to the pillars that are built on the area without intermediate floor, on the facades. Their cross-section is 30 x 50 cm and they are located in 8.0 m distance from each other or from the primary pillars.

Reinforced concrete intermediate floor beams of 16 meter span are put on the pillars or on their short consoles. The floor beams are either (TP74/120) or rectangle (50x120cm) cross-section. The prefabricated reinforced concrete planks with circular hollows are seated on them with a span of 8 meter (on certain locations 10 m) and 25 cm height. On the planks 7 cm thick top concrete layer is applied.

Short principal beam reinforced concrete structural skeleton was used in this hall i.e. the principal beams (ITP144/60) were installed on the shorter, 16 m line of the 16×24 m base grid and the purlins (TP120/50) in the 24 m direction, with 5.33 m divisions.

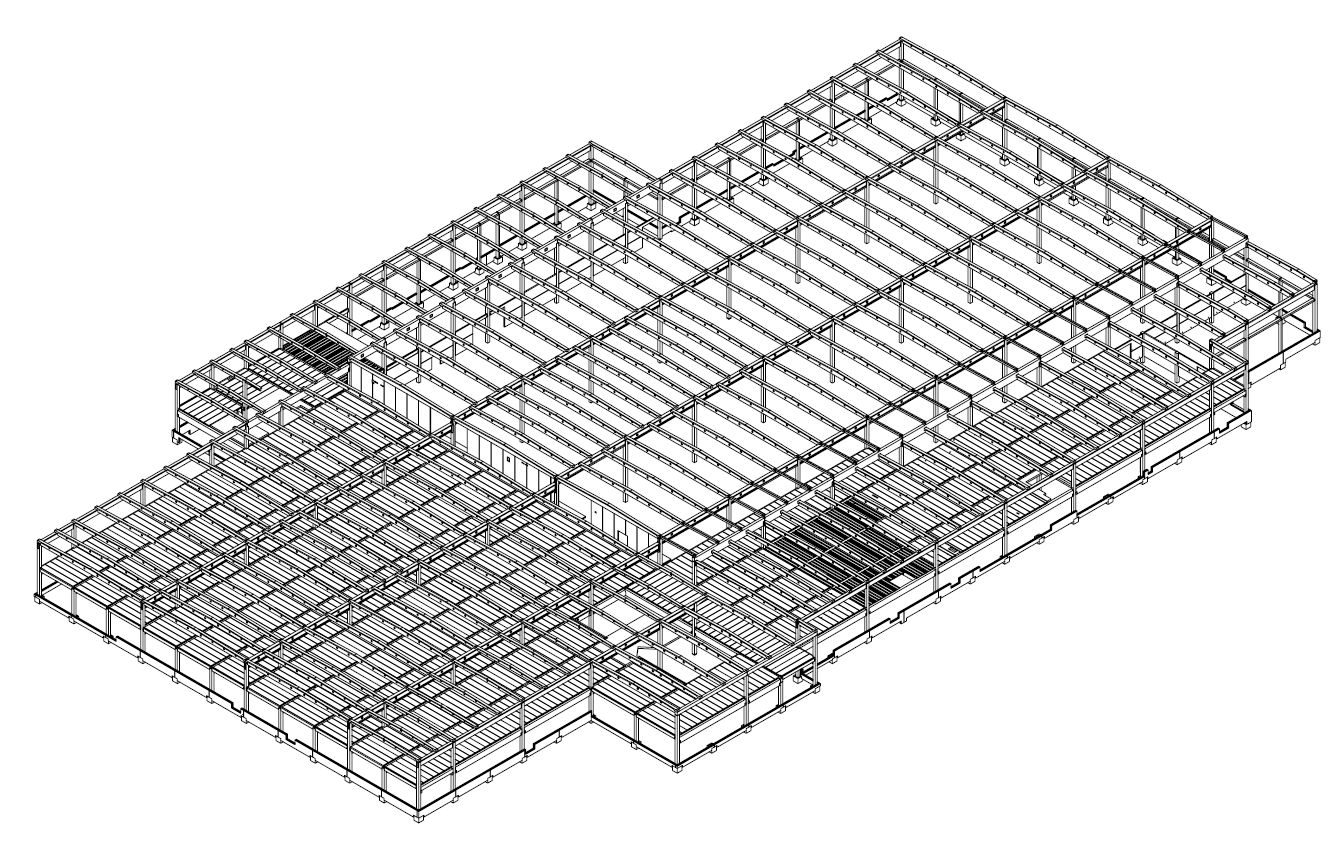

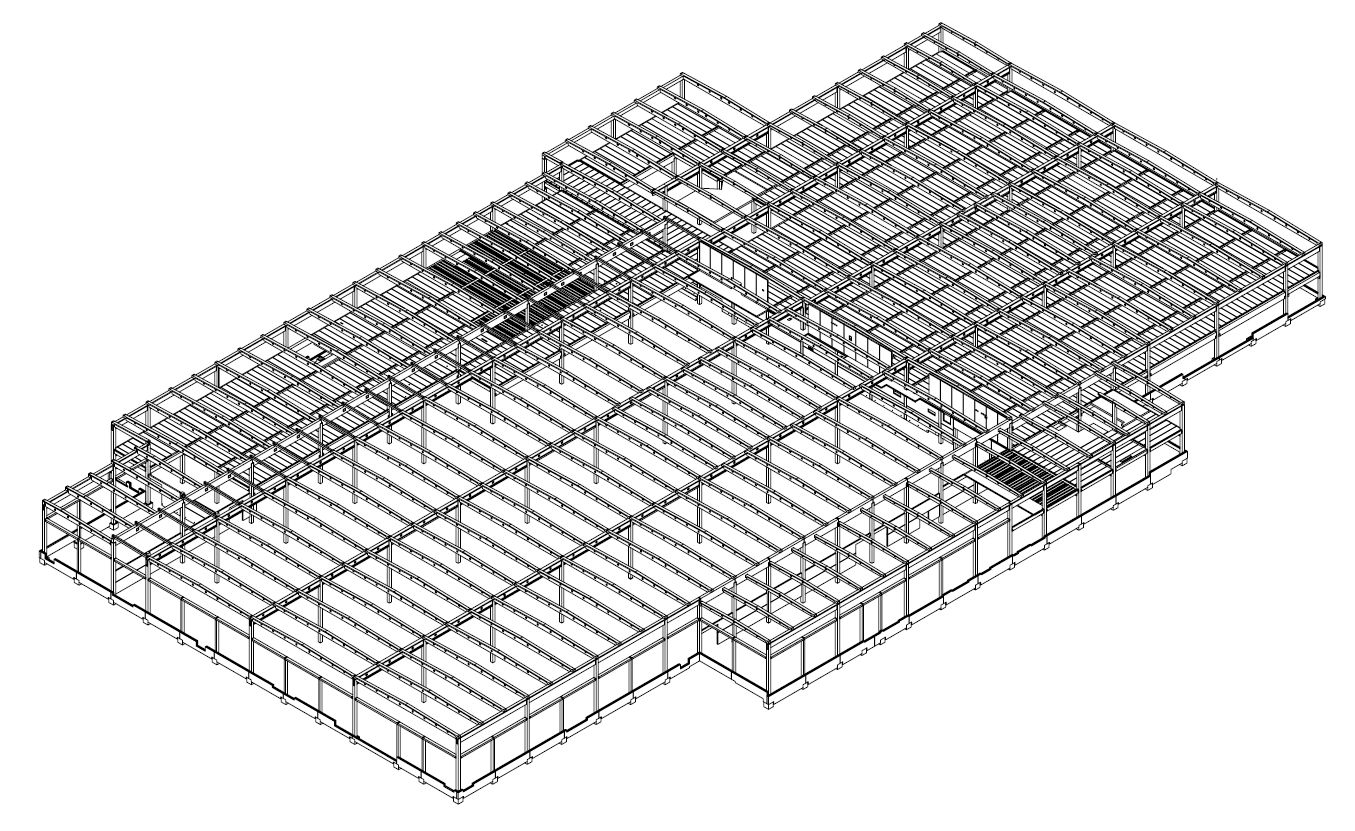

During the design phase we prepared the 3D model of the complete reinforced concrete shell at first so that we could provide the design/execution partners with it before preparing the product designs. Simultaneously with preparing the model we prepared the statics calculations. On the one hand this consisted of determining the dimensions of the prestressed reinforced beams because there are beams of large span in the building. It is important for us to work with economical segments and dimensions.

Processing started after that; allocation (designation) designs were prepared of the reinforced concrete components – bowls, pillars, intermediate floor, roof beams, pedestal components, docking stations, firewalls, stairs, armatures etc. – and then shuttering and reinforcement plans were prepared.

Axonometry

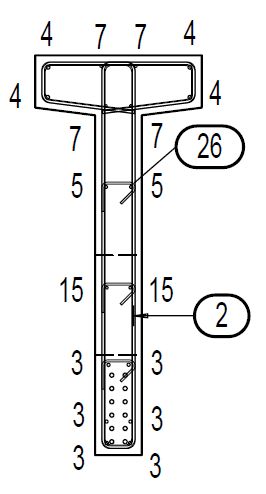

Common building elements used in the project

Cross-section of pillars

Cross-section of principal beam

Cross-section of perlin