Project Description

Krones hall, Debrecen, 2018

The Krones production hall is an industrial facility of approximately 40,000 sq.m. with prefabricated reinforced concrete structure. The product development was carried out by Plan31 Mérnök Kft.

The project was implemented in the outer belt area of the city of Debrecen. It consists of two main parts: hall unit and office building. We were dealing with the hall part of it which could be divided into further parts: logistics, manufacturing, assembly and “cold” hall.

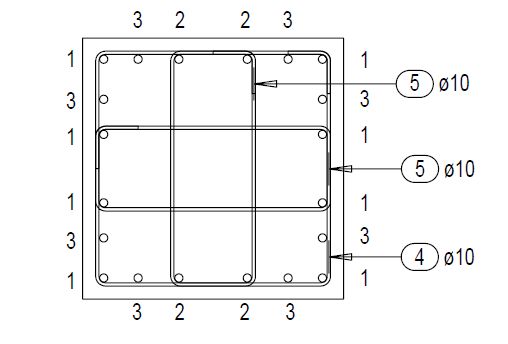

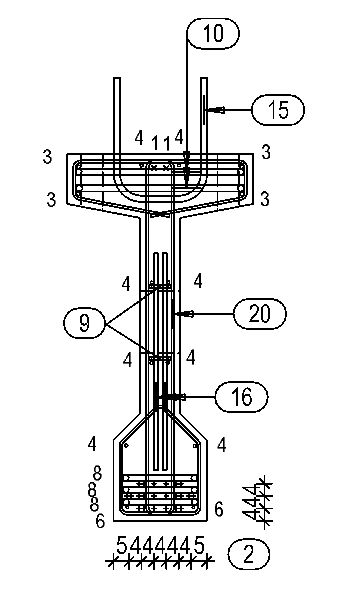

The external floor plan dimensions of the production hall are 168 x 48 m, the upper plane of the attic is 13.5 m, and the clear internal height is 10 m. It consists of two naves and both are equipped with crane bridges. The grid size of the columns is 12 x 24 m, their cross-section is 80 x 80 cm. The external floor plan dimensions of the assembly hall are 156 x 120 m, the upper plane of the attic is 13.5/17.5 m, the clear internal height is 10/14.5 m. It consists of five naves of which four are lower, one is higher and all are equipped with crane bridges. The grid size of the columns is 12 x 24 m, their cross-section is 80 x 80 cm. The external floor plan dimensions of the logistics hall are 120 x 72 m, the upper plane of the attic is 20 m, and the clear internal height is 15.5 m. It consists of one nave with high-bay warehouse function indoors. The grid size of the columns is 12 x 24 m, their cross-section is 100 x 100 cm.

Long principal beam reinforced concrete structural skeleton was used in this hall i.e. the principal beams (ITS154/60) were installed on the longer, 24 m line of the 12×24 m base grid and the purlins (FTR60) in the 12 m direction, with 4.92 m divisions.

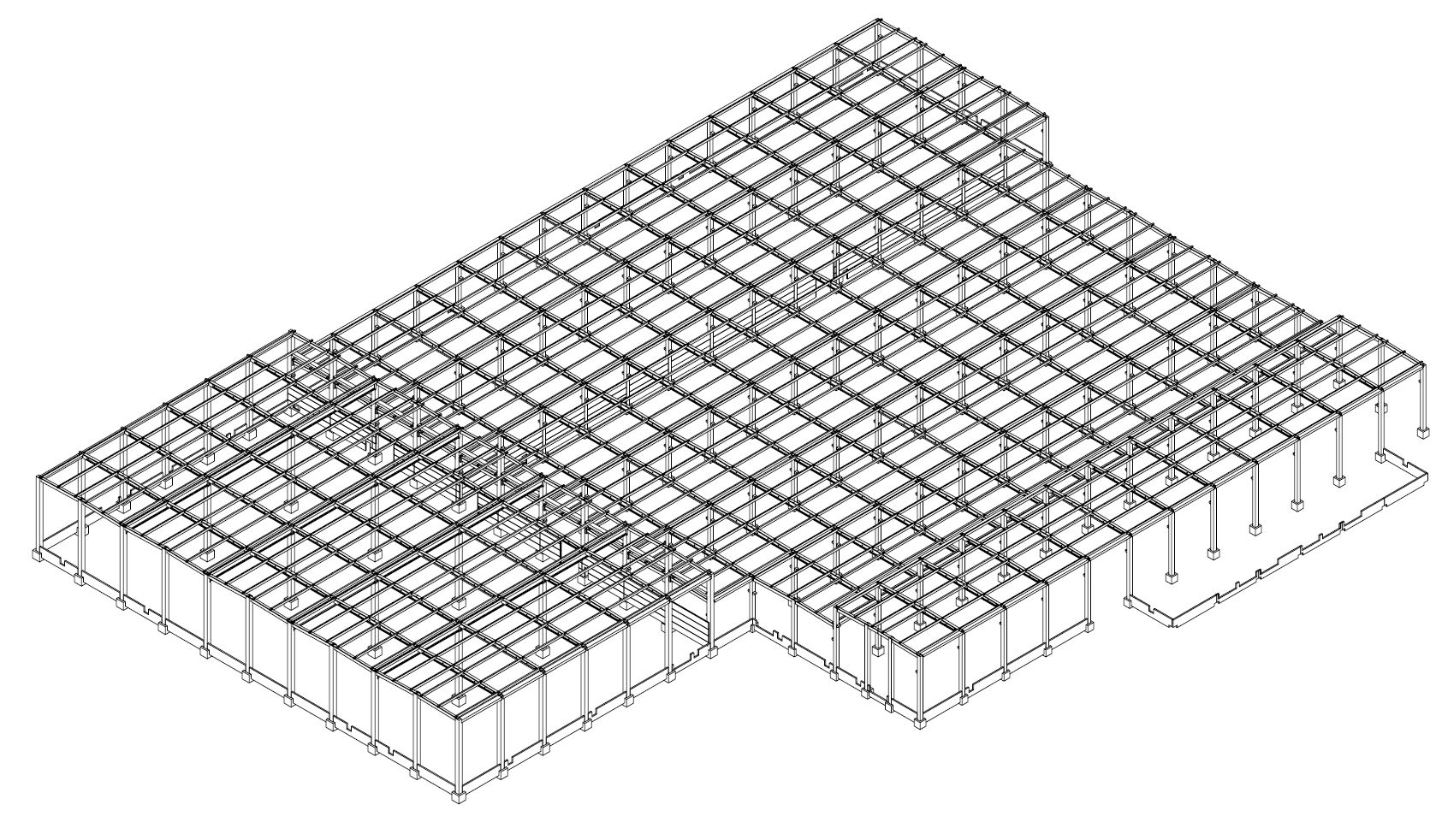

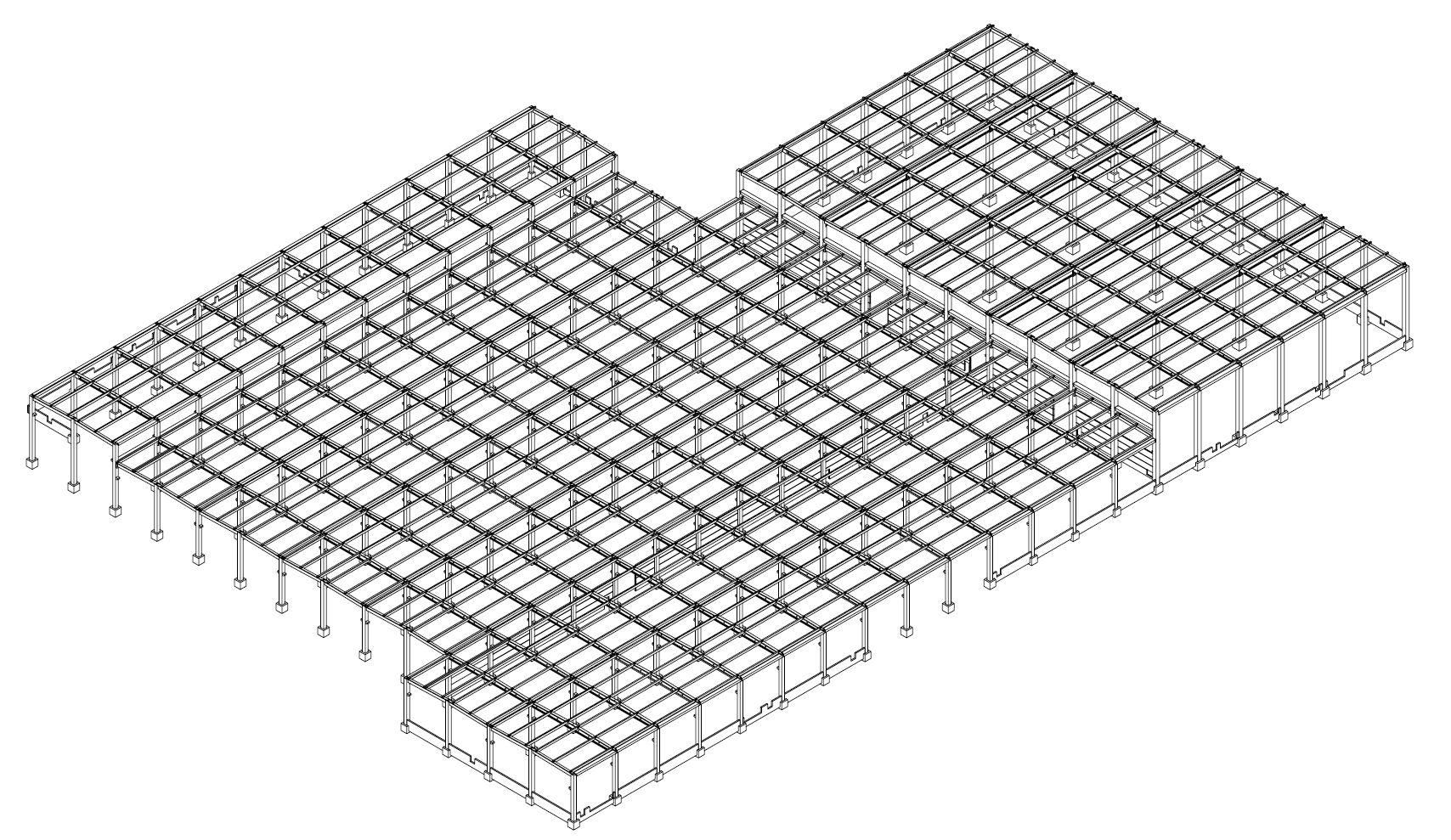

During the design phase we prepared the 3D model of the complete reinforced concrete shell at first so that we could provide the design/execution partners with it before preparing the product designs. Simultaneously with preparing the model we prepared the statics calculations.

Processing started after that; allocation (designation) designs were prepared of the reinforced concrete components – bowls, pillars, loft floor, roof beams, pedestal and wall components, docking stations, firewalls, stairs, armatures etc. – and then shuttering and reinforcement plans were prepared.

Axonometry

Common building elements used in the project

Cross-section of pillars

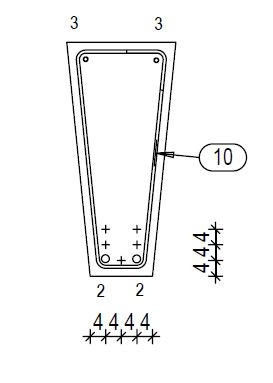

Cross-section of principal beam

Cross-section of perlin